100% Original Welding Rotator With Pu Wheels - 3×3 Meters Welding manipulator – Wuxi Success Detail:

Small Column and Booms are ideal for mounting of a Submerged Arc Welding head or MIG welding head when welding pipework. Larger units enable the welding head to be in an ideal position when welding vessels and boilers. Sizes range from 1.0 x 1.0 to 6 x 6 as standard and sizes up to 10 x 10 can be specified by request.we also can accept customization of all kinds welding machine,such as welding rotator,welding positioner .

Here Below is 2X2 Meters Pipe Welding Manipulator Specification:

Welding Manipulator &Column Boom Manipulator Description:

1. We manufactures a complete line of column and boom welding manipulators which maximize both safety and production with load capacities ranging from 50kg to 1,000kg ( on each end of the boom).

2. ±180°degree column rotation with manual locking at any position.Precise Reach and Lift ranges from 1,000mm to 10,000mm.

3. Seam tracker,Monitor,flux recovery machine and SAW,MIG welding system can incorporate into manipulator welder.

4.Automatic welding manipulators can use together with tank welding rollers,rotary welding positioner.

5. Chain break-resistant and anti-slip device in boom to guarantee safety.

6.100% new from original manufacturer – WUXI SUCCESS MACHINERY EQUIPMENT CO., LTD.

Welding Column Boom Manipulator Advantages From Wuxi Success:

1. Our column boom inverter is brand Danfoss.

2. Our Cylinder Welding Manipulator motor is brand Invertek.

3. Our welding manipulator electronic components is brand Schneider.

4. ISO 9000 & CE certification supported.

Installation And Sale Service:

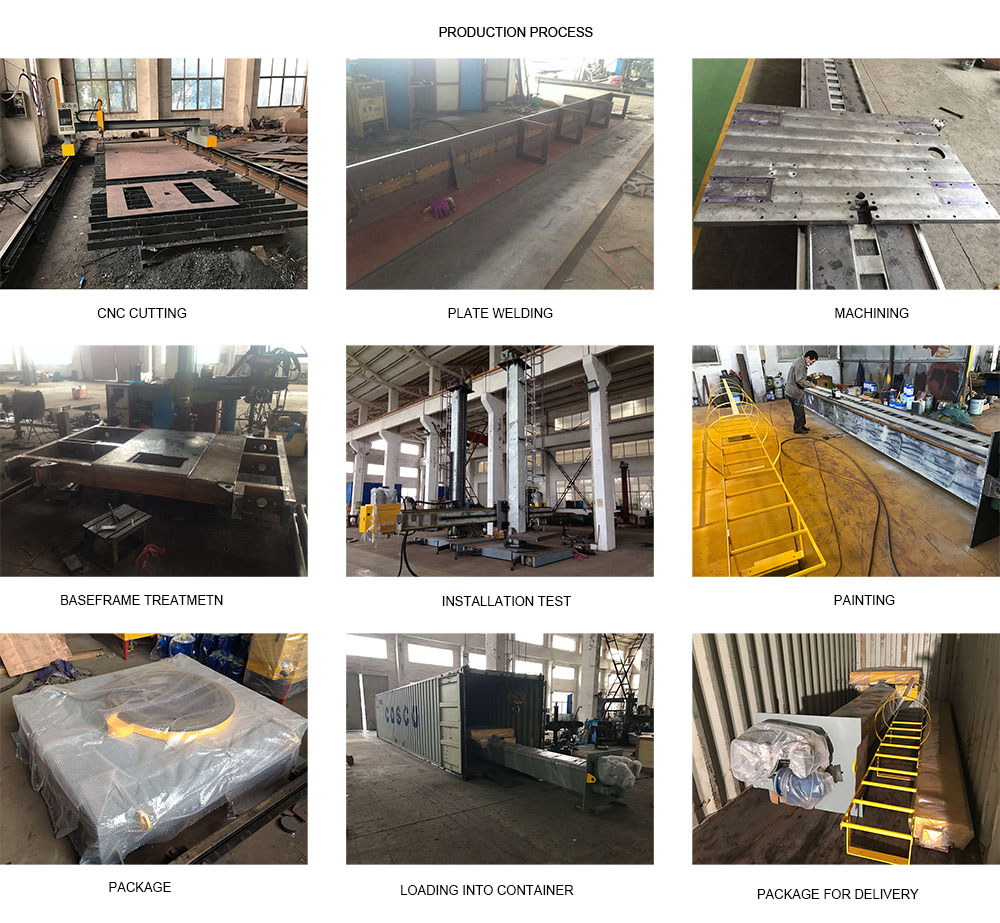

1. The welding manipulator will be fully installed and debugging before package for delivery,We also supply the installation service at your work shop if needed.

2.Professional and experienced engineer team to ensure the advanced design of structure and electric

3. Our products for one year warranty and life long maintenance.

4. We have a large stock of components and parts, easily-worn parts.

5.We can make the fully welding equipment according to your request.

Our Related Products Name:

Welding Column And Boom,Horizontal Pipe Rollers,column and boom,Column Boom Manipulator,Pipe Welding Manipulator,Cross Welding Manipulator,Cylinder Welding Manipulator,Welding Manipulator For Mine,Automatic Feeding Manipulator,Wind Tower Manipulator Machine,pipe welding roller stand, pipe welding roller, pipe turning rolls, pipe welding roller, tube turning rolls, fit up rotator, self-aligned pipe welding roller stand, , self adjustable pipe welding roller stand, self aligned roller stand, wheel frame, roller frame for wind tower welding, conventional pipe welding roller stand, bolt adjustable pipe welding roller stand, sand blasting rotator, painting rotator, fit up rotator,welding positioner,welding column and boom,column boom manipulator,Automatic Feeding Manipulator,Heavy Duty Welding Manipulator,welding manipulator for pipe,Manipulator Welder.

Product detail pictures:

Related Product Guide:

Sheet Metal Fabricators – Hot Tips For Welding Flat Rolled Steel

Pipe Welding: What If It Turned Out The U.S. Will Soon Be The Top Oil Producer In The World?

Our pursuit and enterprise aim would be to "Always fulfill our buyer requirements". We carry on to acquire and layout excellent quality items for the two our old and new clients and realize a win-win prospect for our shoppers in addition as us for 100% Original Welding Rotator With Pu Wheels - 3×3 Meters Welding manipulator – Wuxi Success, The product will supply to all over the world, such as: Cyprus, London, Philippines, We care about every steps of our services, from factory selection, product development & design, price negotiation, inspection, shipping to aftermarket. We have implemented a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our products have been strictly inspected before shipment. Your Success, Our Glory: Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us.

We have worked with many companies, but this time is the best,detailed explanation, timely delivery and quality qualified, nice!