2017 High quality Welding Rotator Construction Plan - 200T Self Aligning Rotator – Wuxi Success Detail:

Self aligned tank turning rolls adjust the wheel centerline setting automatically when the vessel is lowered into place. There are no couplings to change and no pins to remove or replace.Self aligned pipe welding rollers provides constant centerline capabilities which make set-up and alignment quick and easy.The automatically infinitely adjustable centerline settings provide easy alignment for tapered vessels, while the added surface area of 4 wheels per unit provides additional support for thin walled vessels.

Here below is the 40T welding rollers specification:

| Model | SAR-200 |

| Load capacity – Drive | 100 tons maximum |

| Load capacity – Idler | 100 tons maximum |

| Load capacity – Set | 200 tons maximum |

| Rotation capacity | 200 tons maximum |

| Vessels diameter | Min. 1000mm ~ Max.6000mm |

| Rotation speed | 100~1000 mm/min VFD |

| Rotation power | 2*4kw with fan cooling |

| Roller wheels | PU (Polyurethane wheels) |

| Control way | Remote hand control + Foot pedal |

| Input Voltage | 110V ~ 575V Single/3 Phase 50/60Hz |

| Certificate | CE approval |

Machine description:

1. Consist : One powered roller , One idler roller , Electric control system

2. Adjust way : Adjust the pipe diameter automatically with diameter 12 – 110 inches

3. Voltage : 110V - 600 V 50 / 60 Hz 1P / 3P all available

4. Control Way : Remote hand control box / Wireless hand control box

5. Roller Material : Rubber / Steel / PU ( Polyurethane roller for Nonferrous Metals )

6. Original : Wuxi Success Machinery Equipment Co., Ltd supply the welding pipe stands

7. We provide 12month guaranty period for the whole welding machine quality.

Our welding rotators advantage:

1. Our pressure vessels welding rolls inverter is from Danfoss / Yaskawa

2.OurWelding Roller Beds Motor is from Invertek

3.Our welding tank turning rollers Reducer is from China brand

4.Our welding rotators Electric system is from Schneider

Pipe Welding Roll Usage:

1. Medium range series has been engineered for the effective positioning of long cylindrical work-pieces.

2. Oil tanks, pressure vessels, and pipe are applications that utilize turning rolls.

3. Long objects that are not cylindrical may be adapted with the aid of custom designed support rings.

4. We design incorporates overload discs on each wheel that prevent excessive loads from damaging the tires.

Our suggestion:

1. If you want the foot pedal control , please advise me when you send us the inquiry.

2. Movable pipe welding rollers are also available.

3. We suggest you choose the welding column and boom together with the rollers for auto tank welding.

4. Normally under 60 T model we use the Rubber material rollers , upper we use Steel material rollers.

5. If your work piece material is Nonferrous Metals , we suggest PU rollers.

6. Self-aligning pipe welding rollers / Bolt adjsutment / Lead Screw adjustment / Fit up rotators are all available.

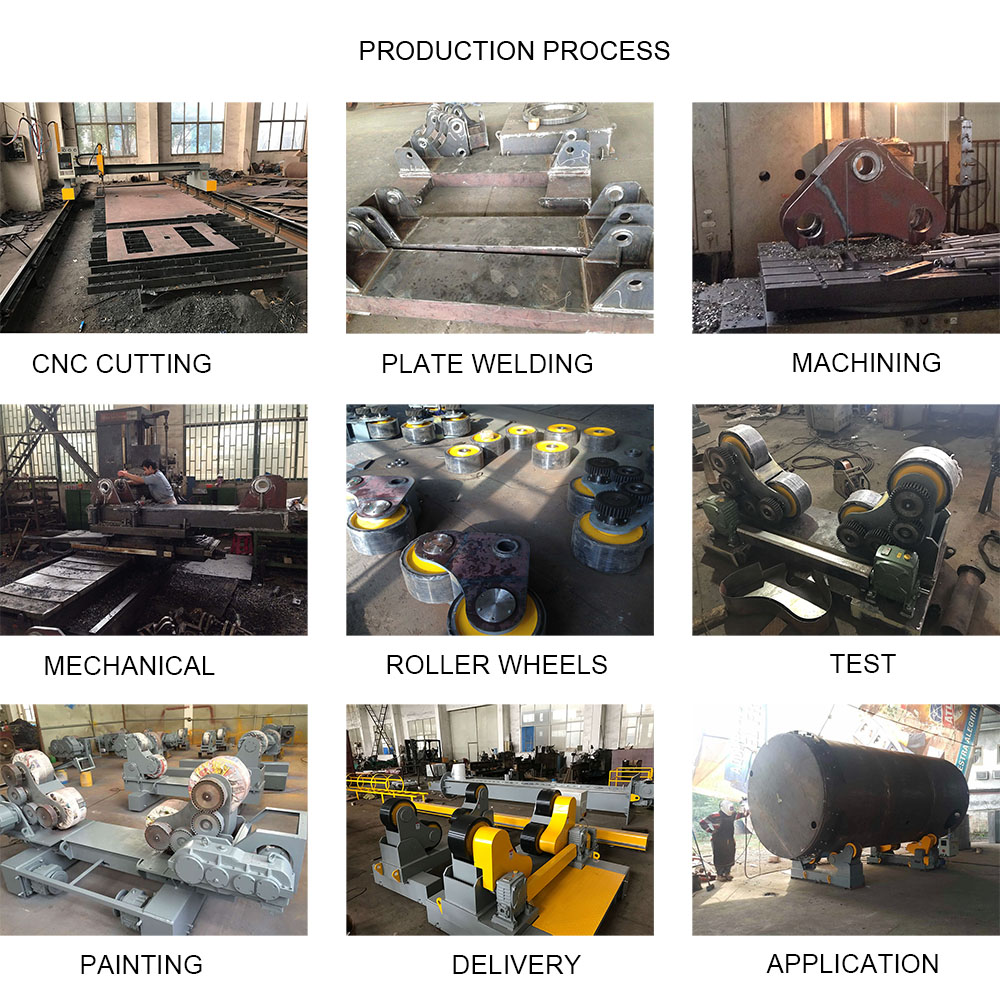

Product detail pictures:

Related Product Guide:

Tips To Consider When Working With The Column Boom Manipulator

The Purpose of Welding Positioners in the Manufacturing Industry

It adheres on the tenet "Honest, industrious, enterprising, innovative" to develop new items frequently. It regards buyers, success as its very own success. Let us produce prosperous future hand in hand for 2017 High quality Welding Rotator Construction Plan - 200T Self Aligning Rotator – Wuxi Success, The product will supply to all over the world, such as: Mali, Porto, Poland, With the development and enlargement of mass clients abroad, now we have set up cooperative relationships with many major brands. We have our own factory and also have many reliable and well-cooperated factories in the field. Adhering to the "quality first, customer first, We are provideing high-quality, low-cost products and first-class service to customers. We sincerely hope to establish business relationship with customers from all over the world on the basis of quality, mutually benefit. We welcome OEM projects and designs.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.

-

Cheap PriceList for Column Boom - 30T Conventi...

View Detail -

Online Exporter Pipe Manipulator Welding - 10T...

View Detail -

Hot Sale for China Chuck Pipe Welding Positione...

View Detail -

Newly Arrival Inflatable Walking Roller - 100T...

View Detail -

China OEM Welding Positioner Chuck - Fit up we...

View Detail -

Wholesale Price China Inflatable Zorb Walking R...

View Detail