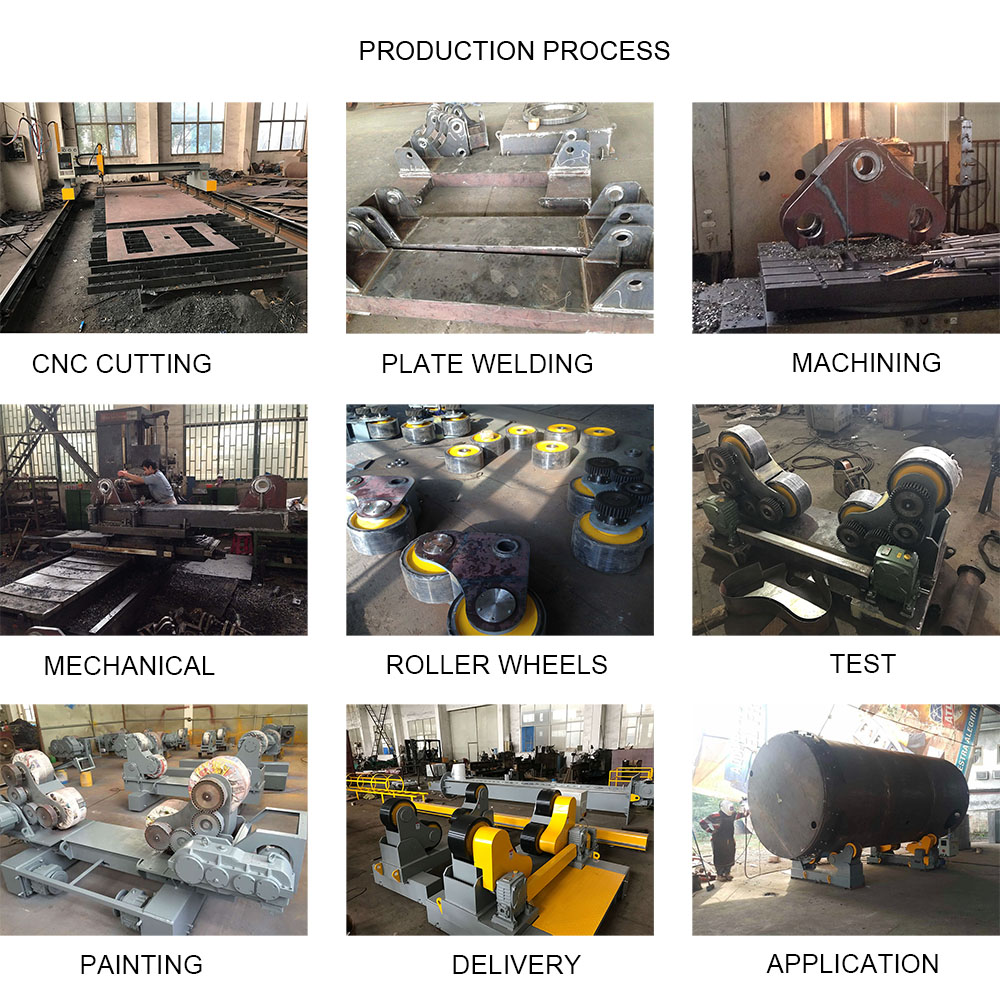

Best quality Mini Excavator Track Rollers - 100T Self Aligning Rotator – Wuxi Success Detail:

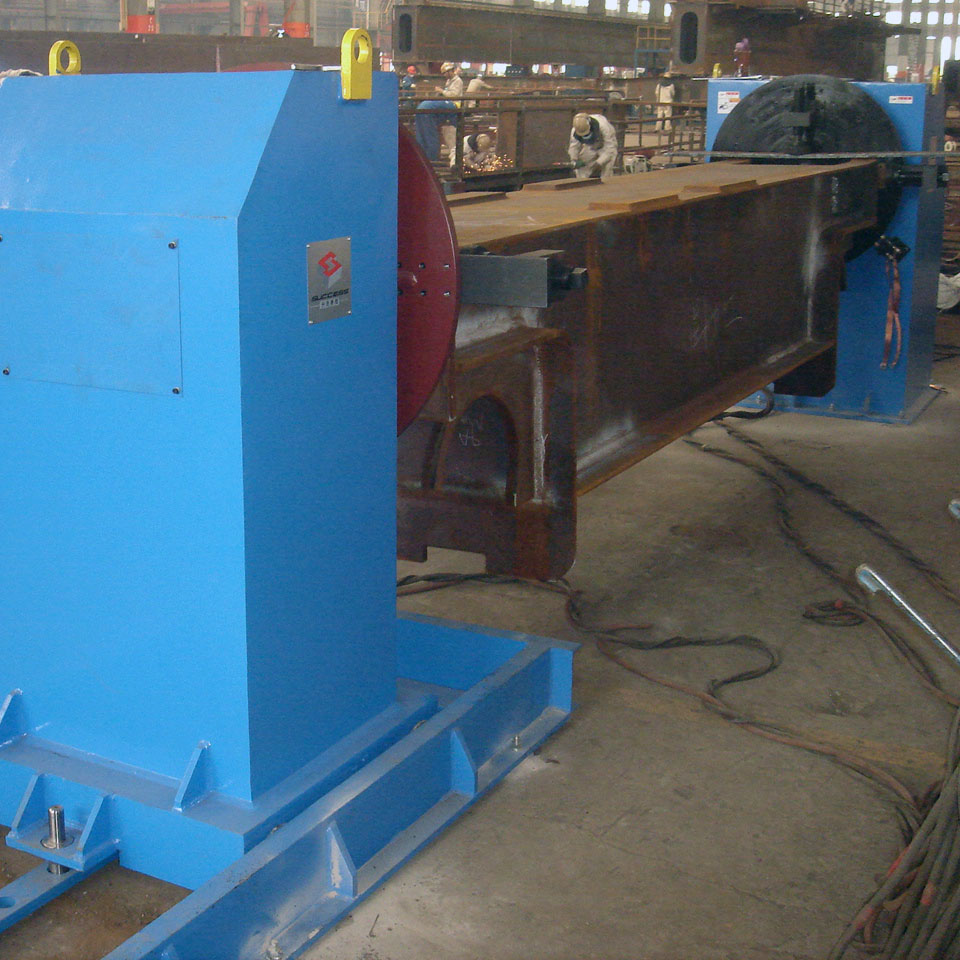

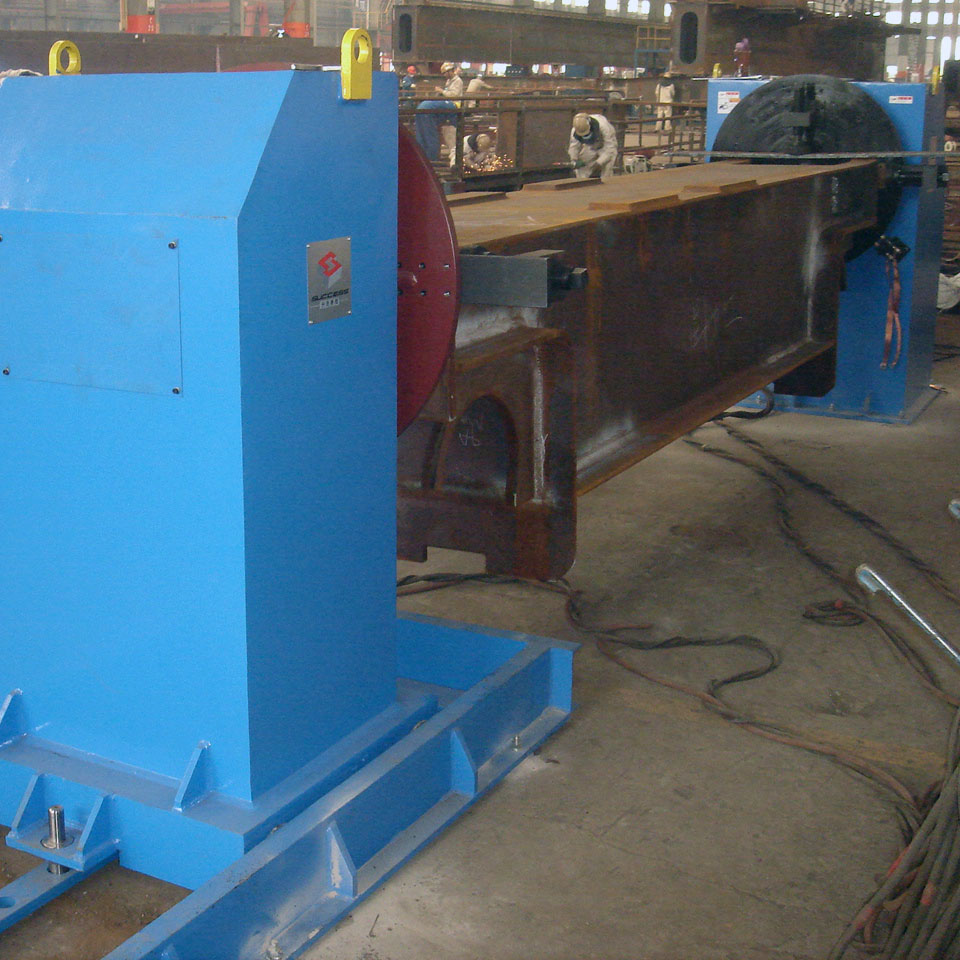

Self-aligning/self centering type.this type welding rotator can suit for the different diameter tank within the range and achieve the stepless speed adjusting under the setted welding parameter via adjust it’s rolls center distance, which has the good character as small noise on the transmission and steady rotation for the working table..Each section supports the vessel / Job on four points ensuring better traction, and on machines of 3 T to 500 T capacity and upwards 50 metric tonnes all four wheels of the drive section are positively driven. This four point suspension is an added advantage when on handling thin walled vessels.

Here below is the 40T welding rollers specification:

| Model | SAR-100 |

| Load capacity – Drive | 50 tons maximum |

| Load capacity – Idler | 50 tons maximum |

| Load capacity – Set | 100 tons maximum |

| Rotation capacity | 100 tons maximum |

| Vessels diameter | Min. 1000mm ~ Max.5500mm |

| Rotation speed | 100~1000 mm/min VFD |

| Rotation power | 2*2.3kw with fan cooling |

| Roller wheels | PU (Polyurethane wheels) |

| Control way | Remote hand control + Foot pedal |

| Input Voltage | 110V ~ 575V Single/3 Phase 50/60Hz |

| Certificate | CE approval |

Self Aligning Tank Turning Welding Rollers Products feature:

1. One drive piece roller & one idler piece roller are packaged together as one set for sale.

2. Remote hand control, Radio hand control & Foot pedal control are all avaialble.

3. Self adjustment for different diameter vessels without manual adjust, more convenient.

4. Stepless adjustable speed of the driven part with rotation speed 100~1000mm/min .

5. Top-class electronic components from Schneider to ensure long time using life.

6. 100% new from original manufacturer – WUXI SUCCESS MACHINERY EQUIPMENT CO., LTD.

Our welding rotators advantage:

1. Our pipe turning rolls inverter is from Danfoss / Yaskawa

2.Our fit up welding rotator Motor is from Invertek

3.Our welding tank turning rolls Reducer is from China brand

4.Our welding rollers Electric system is from Schneider

Widely application:

These welding rotators are used for rotating piping fitting,Stainless Steel Tank Polishing, ,turning roller painting and tank turning rolls assembly of cylindrical roller shell. Chemical & fuel storage tank fabrication, Pressure vessels welding, Wind power fabrication.

Attention More:

1. Movable rotators can auto move on the rails for the third single pipe butt welding.

2. The rollers will be controled by Hand Remote Control Box or Wireless Control Box.

3. If your single pipe length more then 8M , then you should use 1 powered with 2 idlers to support.

4. All our pipe welding rotators have 20% over weight design, but we suggest used on the safety rangs.

5. We have strong delivery team, including the Sea freight and Air transportation. Door to door available.

6. Just advise me your desitination port then we will give you the final CIF price.

Installation and after sale service:

1.The rotator will be fully installed before package for delivery in wooden case

2.We also supply the installation service at your work shop if needed.

3.One year warranty for welding rotator quality and free supported for spare parts.

4.Overseas agent is available in Italy and America market.

Product detail pictures:

Related Product Guide:

Sheet Metal Fabricators – Hot Tips For Welding Flat Rolled Steel

Turning Rolls Are the Best Welding Supplies

We always continually offer you by far the most conscientious customer service, and the widest variety of designs and styles with finest materials. These attempts include the availability of customized designs with speed and dispatch for Best quality Mini Excavator Track Rollers - 100T Self Aligning Rotator – Wuxi Success, The product will supply to all over the world, such as: Greenland, Sweden, Adelaide, Providing Quality Products, Excellent Service, Competitive Prices and Prompt Delivery. Our products are selling well both in domestic and foreign markets. Our company is trying to be one important suppliers in China.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!

-

Competitive Price for High Quality Vessel Weldi...

View Detail -

OEM manufacturer Industrial Arc Welding Manipul...

View Detail -

High Quality High Adjust Welding Positioner - ...

View Detail -

Fast delivery Inflatable Water Roller Game - 6...

View Detail -

Newly Arrival Power Transformer Tank Making - ...

View Detail -

Discountable price 60t Welding Rotator - 3000k...

View Detail