Bottom price Discon Welding Roller - Welding manipulator – Wuxi Success Detail:

Our welding column boom manipulator size can up to 10×12 meters maximum. Here is 4×4 meters for your reference:

Here Below is 4X4 Meters Column Boom Welding Manipulator Specification:

Welding Column And Boom Manipulator Description:

1. Column and boom manipulater is used for inside, outside,longitudinal & circumferential welding .

2. ±180° degree column rotation with manual locking at any position.

3. Column boom work with motorized cross slides to adjust the welding gun position.

4.Automatic welding manipulators can use together with tank welding rollers,rotary welding positioner.

5. Braking device can ensure column work in safe environment.

6.Customized manipulator requirements are accepted.

Column Boom Welding Manipulator Advantages From Wuxi Success:

1. Our welding manipulator inverter is from Danfoss.

2. Our column and boom motor is from Invertek.

3. Our automatic manipulator electronic components is from Schneider.

4. Seam tracker,Monitor,flux recovery machine and SAW,MIG welding system can incorporate into manipulator welder.

Welding Column And Boom Features:

1. Welding manipulators are the automatic welding equipment composed together with welding power.

2. It is widely used in industries as boiler, pressure vessel, petro chemical machinery for welding of inner and outer longitudinal seams and circumferential seams.

3. The automatic welding manipulator is design for four different structure type: Fixed type, fixed rotation type, fixed movable type and movable rotation type.

4. Motorized cross slider 100*100mm fine adjustment stroke to welding gun.

5. Worm gearbox for vertical travel via AC motor, complete with brake for added safety.

Why Choose Wuxi Success Machinery Equipment CO.,LTD:

1.We promise honest and fair, it’s our pleasure to serve you as your purchasing consultant.

2.We guarantee punctuality, quality and quantities strictly implement the terms of contract.

3.Professional and experienced engineer team to ensure the advanced design of structure and electric

4. High tensile roller chain used for vertical travel with the addition of a counter balance system with the column that provides smooth, effortless travel.

5.Commissioning and testing before delivery.

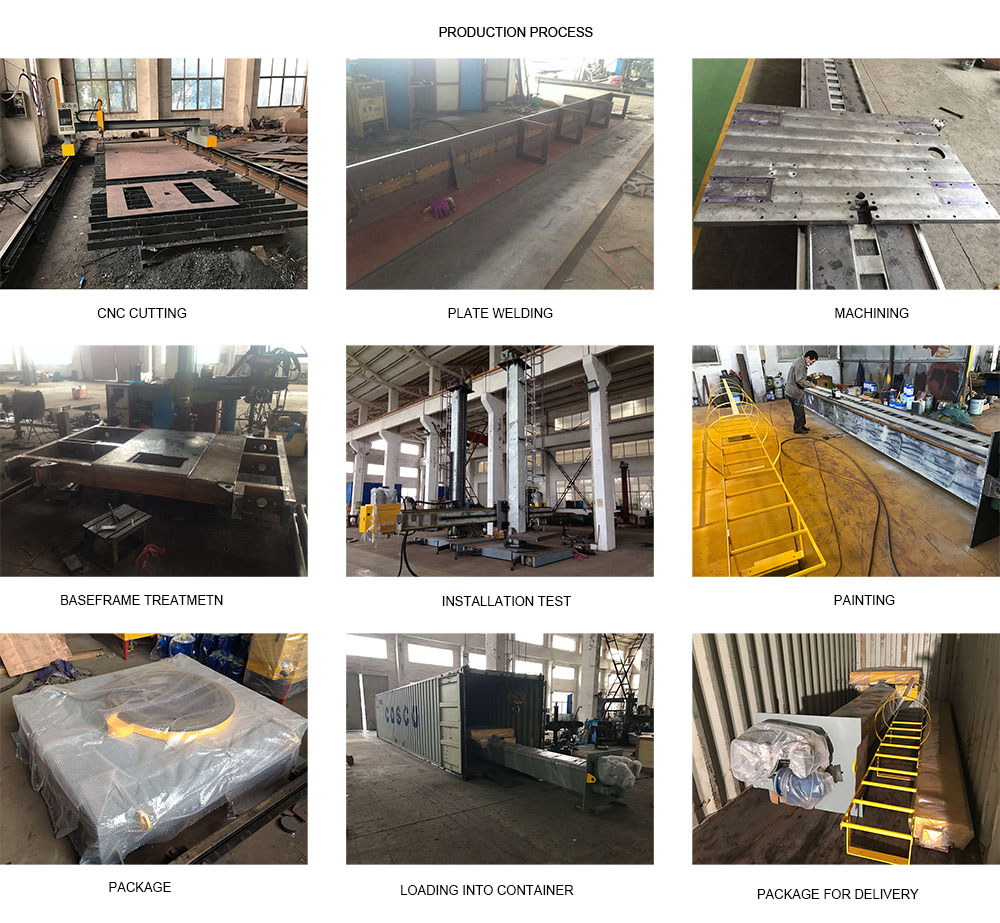

Product detail pictures:

Related Product Guide:

The Purpose of Welding Positioners in the Manufacturing Industry

Turning Rolls Are the Best Welding Supplies

Our rewards are lower costs,dynamic profits team,specialised QC,potent factories,high-quality services for Bottom price Discon Welding Roller - Welding manipulator – Wuxi Success, The product will supply to all over the world, such as: Albania, Jamaica, Sudan, To let customers be more confident in us and get the most comfortable service, we run our company with honesty, sincerity and best quality . We firmly believe that it is our pleasure to help customers to run their business more successfully, and that our professional advice and service can lead to more suitable choice for the customers.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.