Competitive Price for Two Roller Mixing Mill - 10T Gear tilt positioner – Wuxi Success Detail:

Gear tilt welding positioner is consisting of rotary worktable, titling device and electric control system. The work-piece can be reach to the best position through worktable rotary and titling device.The worktable rotate controlled by step-less frequency conversion to reach a best welding speed.The positioner can also be designed in hydraulic driven system. It is usually used in very heavy duty work piece welding industry. By the hydraulic cylinder, the table can tilting smoothly and hold the work piece tightly.

Here Below is 10T Gear Tilt Pipe Welding Positioners Specification:

Position Changing Welding Machine Description:

1. The worktable could be rotated ( in 360°) or tilted (in 0-120°) allowing work piece to be welded at the best position,and motorized rotation speed is VFD control.

2.Control system has three options: the key figures controlled, digital controlled switching and switching relays controlled.

3. Voltage standard is 380V-3PH-50HZ, but we can make 110-575V as per your requirement.

4.Can add a chuck in the welding table to fix (clamp) the work-piece well.

5.It’s Convenient for assembling intricate sub-assemblies,and ideal for in conjunction with welding manipulator Column & Boom.

6.100% new welding positioner machine from Wuxi Success Machinery Equipment CO.,LTD

Our Welding Table With Positioner Competitive Advantage:

1. Welding turning table Inverter is from Danfoss / Yaskawa.

2. Automatic welding positioner Electric system is from Schneider.

3.Welding turning table Motor is brand Invertek.

4.Giving you the competitive price.

5.CE certificates to European market and America.

Clamps For Reference:

1. We have 3 jaws or 4 jaws chucks for chosen, and pipe diameter from 50 mm to 1200 mm.

2. Special clamps are available,but we have to design according to your work piece detail drawings.

3. We also have Hydrulic lifting welding positioner,welding turntable for reference.

Welding Table With Positioner Application:

1. Pressure vessels welding.

2. Pipe manufacturing industries welding.

3. Wind power fabrication welding.

4. Chemical & fuel storage tank fabrication welding.

5. Any heavy cylindrical job.

Installation and after sale service:

1.The welding positioner will be fully installed and debugging before package for delivery.

2.We also supply the installation service at your work shop if needed.

3.One year warranty for welding rotator quality and free supported for spare parts.

4.Overseas agent is available in Italy and America market.

5. We also supply door to door installation service, but need customer to pay the out and back flight .

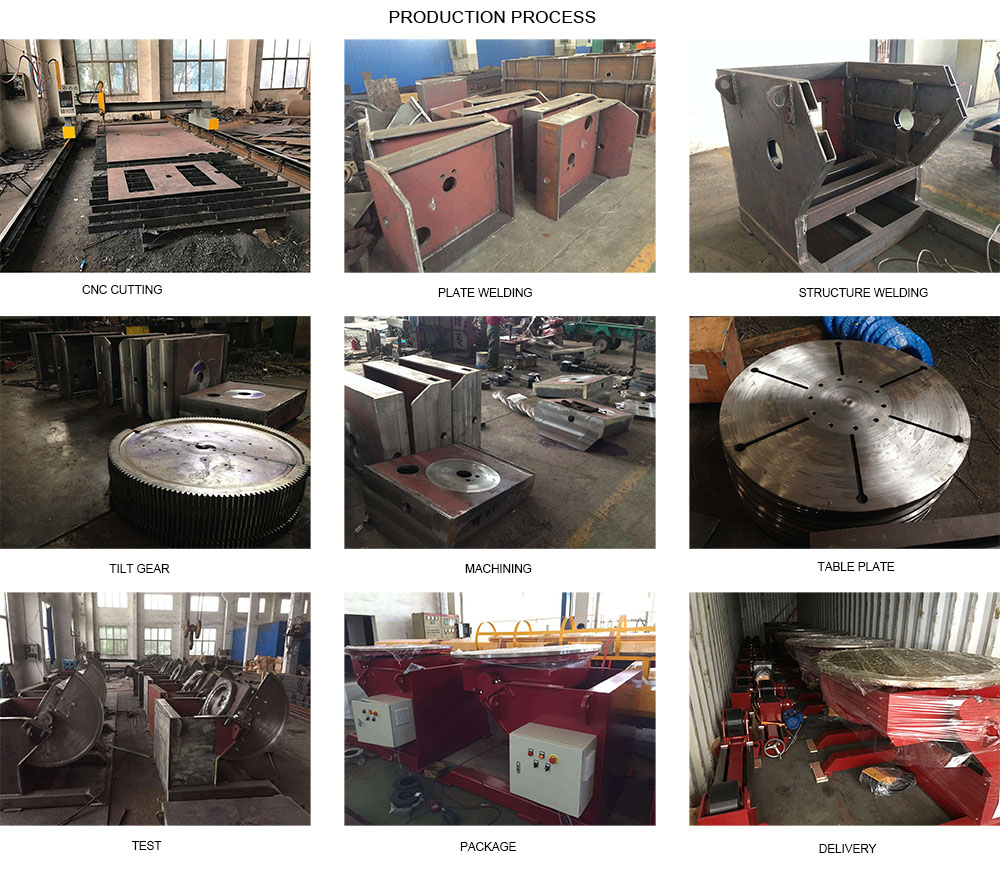

Product detail pictures:

Related Product Guide:

Sheet Metal Fabricators – Hot Tips For Welding Flat Rolled Steel

Tips To Consider When Working With The Column Boom Manipulator

Our development depends on the advanced equipment ,excellent talents and continuously strengthened technology forces for Competitive Price for Two Roller Mixing Mill - 10T Gear tilt positioner – Wuxi Success, The product will supply to all over the world, such as: Kenya, New Zealand, Turkey, Our objective is "to supply first step products and best service for our customers, thus we are sure you must have a margin benefit through cooperating with us". If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

We have worked with many companies, but this time is the best,detailed explanation, timely delivery and quality qualified, nice!