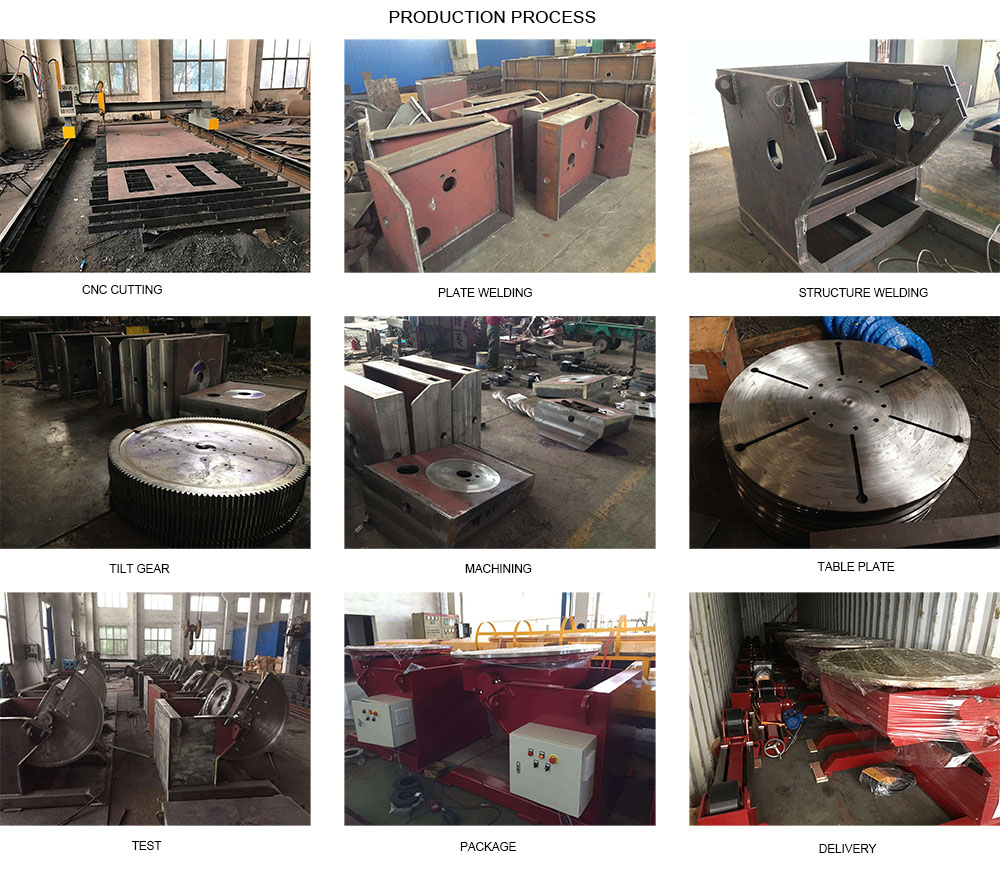

Factory making High Frequency Machine - 1000kg Gear tilt positioner – Wuxi Success Detail:

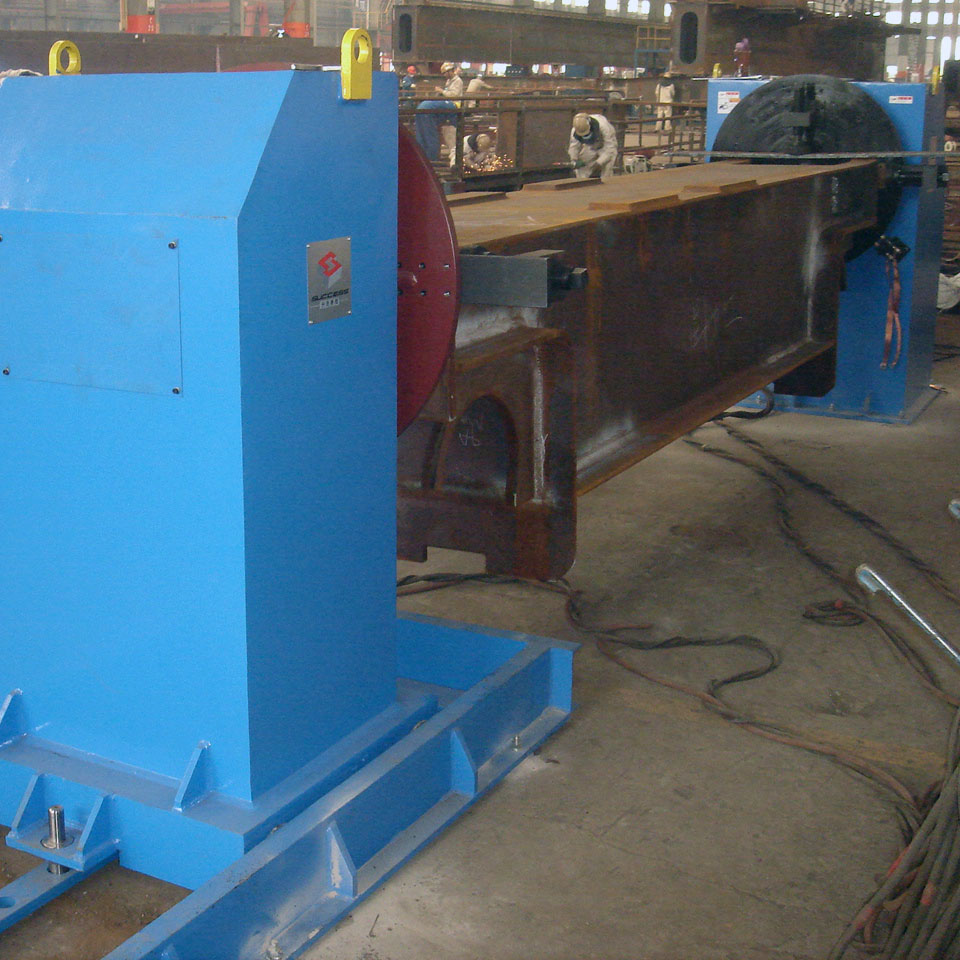

Welding positioner is consisting of rotary worktable, titling device and electric control system. Positioners provide steel fabrication shops with the most up-to-date equipment for placing bulky fabrications in the ‘down hand’ position in the shortest possible time without the use of cranes and manpower. The positioners tables rotate at accurate and constant variable speeds and tilt through 135° with a high C.G. load rating covering almost all anglers for welding any angular job placed on it. The positioner can also be designed in hydraulic driven system. It is usually used in very heavy duty work piece welding industry. By the hydraulic cylinder, the table can tilting smoothly and hold the work piece tightly.

Here Below is 1000KG Welding Positioners Specification:

Automatic Pipe Welding Positioner Description:

1. The worktable could be rotated ( in 360°) or tilted (in 0-120°) allowing work piece to be welded at the best position,and motorized rotation speed is VFD control.

2.Remote hand control box with digital rotation speed readout & foot pedal control for tilting control.

3.Stepless adjustable speed of the table rotation. Top-class electronic components from Schneider.

4. Can add a chuck in the welding table to fix (clamp) the work-piece well.

5. The welding positioner can work with welding column & boom to realize the automatic special purpose welding center.

Our Welding Rotator Welding Positioner Competitive Advantage:

1.Our chuck welding positioners’ Inverter is from Danfoss / Yaskawa.

2.Our positioner weldings’ Motor is from Invertek.

3.Our positioners’ Electric system is from Schneider.

4. CE certificates to European market and CO certificates with welding positioner to Middle East market.

Clamps For Reference:

1. We have 3 jaws or 4 jaws chucks for chosen, and pipe diameter from 50 mm to 1200 mm.

2. Special clamps are available,but we have to design according to your work piece detail drawings.

3. We also have Hydrulic lifting welding positioner,welding turntable for reference.

More Questions Customers May Concerned:

Q1 : What about the transportion?

A : 1. Fully packaged in wooden case to anti damage during the transportational process .

2. Usually we take seaway ,cause its more convenient and cheaper for big machine.

3. Door to door delivery service is also available.

Q 2: What is your warranty and after sale service ?

A : 1. All our equipments with One Year Warranty time , fully test at our work shop before delivery.

2. If you have any questions on the installation , you will get our engineers respond within 24 hours.

Q3: Can your machine or other products be customized?

A : yes, we are a professional manufacturer specializes in welding equipments about 15 years. We have a strong design team to meet requirements of customers.

Related Product Name:

Welding Column And Boom,Manipulators And Robots,Horizontal Pipe Rollers,column and boom,Column Boom Manipulator,Manipulators And Robots,Pipe Welding Manipulator,Cross Welding Manipulator,Cylinder Welding Manipulator,Welding Manipulator For Mine,Automatic Feeding Manipulator,Wind Tower Manipulator Machine.welding manipulator for pipe…

Product detail pictures:

Related Product Guide:

Tips To Consider When Working With The Column Boom Manipulator

Turning Rolls Are the Best Welding Supplies

It truly is a great way to improve our merchandise and repair. Our mission should be to create imaginative products to prospects with a excellent knowledge for Factory making High Frequency Machine - 1000kg Gear tilt positioner – Wuxi Success, The product will supply to all over the world, such as: Finland, Sweden, Gabon, Taking the core concept of "to be the Responsible". We will redound up on society for high quality products and good service. We will initiative to participate in international competition to be a first- class manufacturer of this product in the world.

Good quality, reasonable prices, rich variety and perfect after-sales service, it's nice!