Factory wholesale Casing Rotator For Foundation - 4×4 Meters Welding manipulator – Wuxi Success Detail:

Welding Column&Boom Manipulators of Wuxi Success stands out not only for innovation in design and quality of manufacture, but also for reliability and robustness. It can realize automatic welding incorporate with SAW, MAG and TIG welding systems, and extensively applied in pressure vessel, metallurgy, power, chemical industry, wind tower, piping system and others lines.

Here Below is 4X4 Meters Column Boom Welding Manipulator Specification:

Welding Column And Boom Manipulator Description:

1. Column and boom manipulater is used for inside, outside,longitudinal & circumferential welding .

2. ±180° degree column rotation with manual locking at any position.

3. Column boom work with motorized cross slides to adjust the welding gun position.

4.Automatic welding manipulators can use together with tank welding rollers,rotary welding positioner.

5. Braking device can ensure column work in safe environment.

6.Customized manipulator requirements are accepted.

Column Boom Welding Manipulator Advantages From Wuxi Success:

1. Our welding manipulator inverter is from Danfoss.

2. Our column and boom motor is from Invertek.

3. Our automatic manipulator electronic components is from Schneider.

4. Seam tracker,Monitor,flux recovery machine and SAW,MIG welding system can incorporate into manipulator welder.

Welding Column And Boom Features:

1. Welding manipulators are the automatic welding equipment composed together with welding power.

2. It is widely used in industries as boiler, pressure vessel, petro chemical machinery for welding of inner and outer longitudinal seams and circumferential seams.

3. The automatic welding manipulator is design for four different structure type: Fixed type, fixed rotation type, fixed movable type and movable rotation type.

4. Motorized cross slider 100*100mm fine adjustment stroke to welding gun.

5. Worm gearbox for vertical travel via AC motor, complete with brake for added safety.

Why Choose Wuxi Success Machinery Equipment CO.,LTD:

1.We promise honest and fair, it’s our pleasure to serve you as your purchasing consultant.

2.We guarantee punctuality, quality and quantities strictly implement the terms of contract.

3.Professional and experienced engineer team to ensure the advanced design of structure and electric

4. High tensile roller chain used for vertical travel with the addition of a counter balance system with the column that provides smooth, effortless travel.

5.Commissioning and testing before delivery.

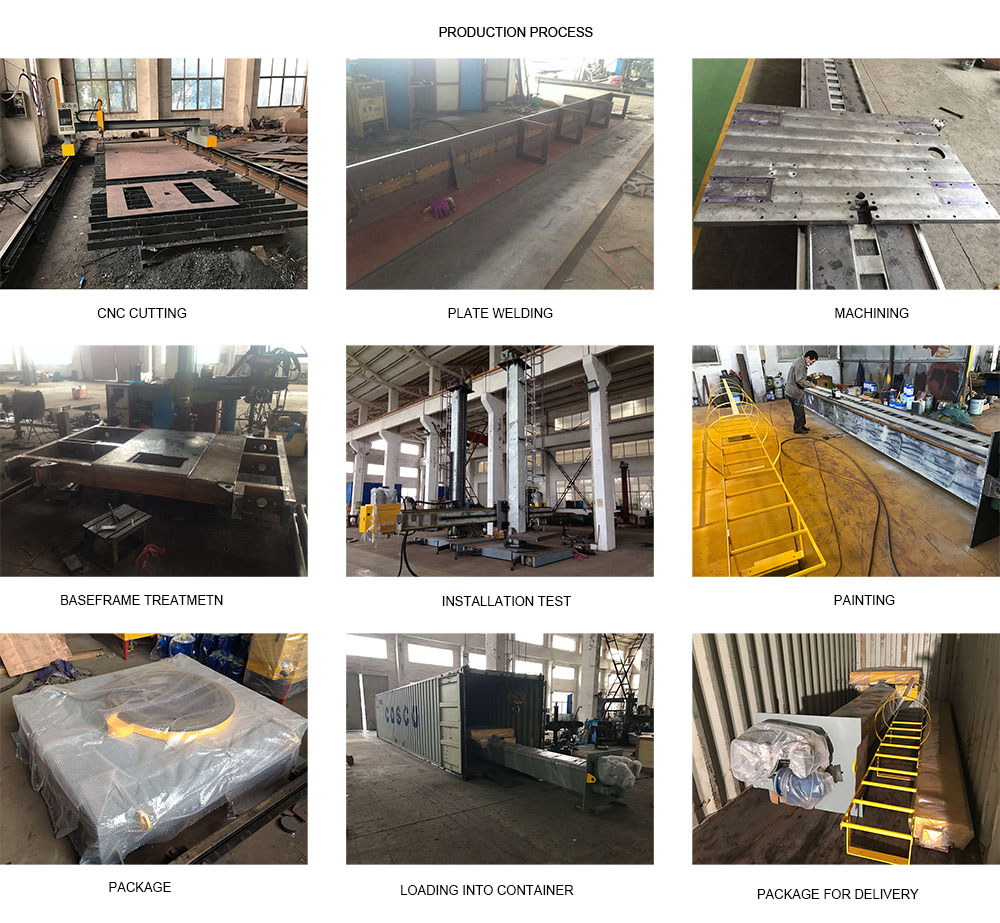

Product detail pictures:

Related Product Guide:

Sheet Metal Fabricators – Hot Tips For Welding Flat Rolled Steel

Pipe Welding: What If It Turned Out The U.S. Will Soon Be The Top Oil Producer In The World?

We can easily usually fulfill our respected customers with our very good top quality, very good price tag and excellent support due to we have been more expert and much more hard-working and do it in cost-effective way for Factory wholesale Casing Rotator For Foundation - 4×4 Meters Welding manipulator – Wuxi Success, The product will supply to all over the world, such as: South Africa, Kuala Lumpur, Dubai, Look forward to the future, we'll focus more on the brand building and promotion . And in the process of our brand global strategic layout we welcome more and more partners join us, work together with us based on mutual benefit. Let's develop market by fully utilizing our in depth advantages and strive for building.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.