Factory wholesale Mig Welding Feed Roller - 60T Self Aligning Rotator – Wuxi Success Detail:

This welding rotator has two types including self alignment and adjustable.This series is self-alignment/self centering type. These pipe welding rollers are used for the rotation and positioning of heavy, rotationally symmetrical workpieces like tanks, pipes or boilers for further machining or welding.

Here Below is 60T Pipe Turning Welding Rollers Specification:

| Model | SAR-60 |

| Load capacity – Drive | 30 tons maximum |

| Load capacity – Idler | 30 tons maximum |

| Load capacity – Set | 60 tons maximum |

| Rotation capacity | 60 tons maximum |

| Vessels diameter | Min. 750mm ~ Max.4800mm |

| Rotation speed | 100~1000 mm/min VFD |

| Rotation power | 2*2kw with fan cooling |

| Roller wheels | PU (Polyurethane wheels) |

| Control way | Remote hand control + Foot pedal |

| Input Voltage | 110V ~ 575V Single/3 Phase 50/60Hz |

| Certificate | CE approval |

Wuxi Success Adjustable Tank Turning Rolls Products Feature:

1.Drive piece roller & one idler piece roller are packaged together as one set for sale.

2.Remote hand control, Radio hand control & Foot pedal control are all avaialble.

3.Our Pipe Welding Roller drive rotation speed is in digital readout.

4.Our Roller Material can customized in Rubber / Steel / PU ( Polyurethane roller for Nonferrous Metals )

5.Manual traveling base frame or motorized traveling base frame is available for longer pipe welding.

6.100% new from original manufacturer – WUXI SUCCESS MACHINERY EQUIPMENT CO., LTD.

Our Welding Machine Spare Parts Brand:

1.Our welding roller Inverter is from Danfoss / Yaskawa

2.Our welding rotator Motor is from Invertek

3.Our Tank rolls Reducer is from China brand

4.Our welding Electric system is from Schneider

Our suggestion For Welding Rotator Beds:

1. Normally welding roller is under 60T model ,we use the PU material rollers , upper we use Steel material rollers.

2. If your work piece material is Nonferrous Metals , we suggest PU rollers.

3. Self-aligning pipe welding rollers / Bolt adjsutment / Lead Screw adjustment / Fit up rotators are all available.

4.We suggest you choose the welding column and boom together with the rollers for auto tank welding.

Installation and after sale service:

1.The rotator will be fully installed before package for delivery in wooden case

2.We also supply the installation service at your work shop if needed.

3.One year warranty for welding rotator quality and free supported for spare parts.

4. Overseas agent is available in Italy and America market.

Our related product:

welding rotator ,weling positioner,welding manipulater,used pipe turning rolls,pressure vessels welding rotator,conventional welding rotator,pipe tank welding totator,rotation welding machine,Hydraulic Roator For Welding,Sand Blast Turning Roll,Automatic Welding Rollers,Tank Roller Welding Machine,Cylinder Pipe Welding Rotator,Conventional Tank Turning Rolls,head tail stock welding positioner,hydraulic welding positioner,lift welding positioer,horizontal welding positioner,Height Adjustment Welding Positioners,Turn Table Welding Positioner,Turn Table Welding Positioner,welding column boom,Auto Welding Boom,Tank Polishing Machine,column and boom,Column And Boom Manipulator,column boom welder

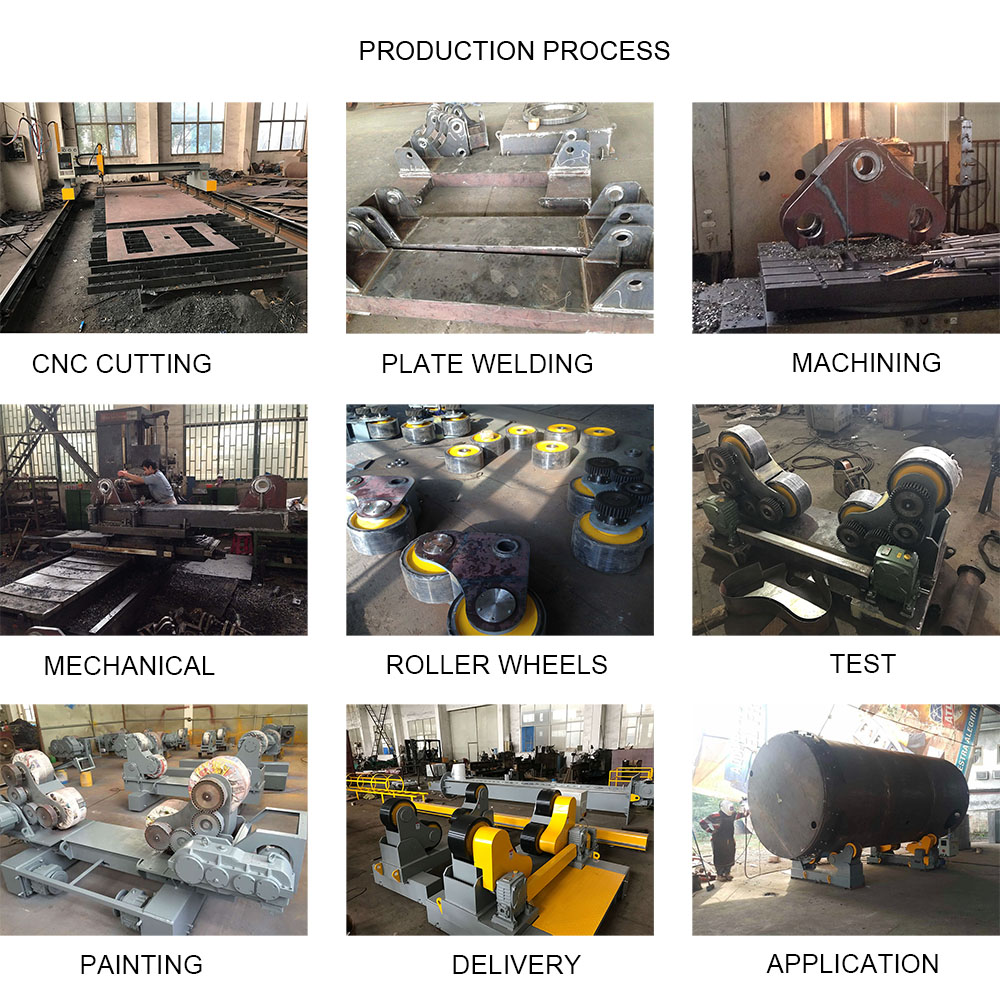

Product detail pictures:

Related Product Guide:

Tips To Consider When Working With The Column Boom Manipulator

The Purpose of Welding Positioners in the Manufacturing Industry

With responsible good quality method, good status and excellent client services, the series of solutions produced by our company are exported to lots of countries and regions for Factory wholesale Mig Welding Feed Roller - 60T Self Aligning Rotator – Wuxi Success, The product will supply to all over the world, such as: Peru, Burundi, Porto, because of our company has been persisting in the management idea of "Survival by Quality, Development by Service, Benefit by Reputation" . We fully realize the good credit standing, the high quality products, the reasonable price and the professional services are the reason that the customers choose us to be their long-term business partner.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.

-

China Supplier 150kg Welding Positioner - 2000...

View Detail -

New Arrival China Cnc Plate Bending Machine Dra...

View Detail -

Factory Free sample Ce Certified Welding Positi...

View Detail -

OEM/ODM Supplier Conveyor Belt Roller - 60T Fi...

View Detail -

100% Original Factory Positioner For Welding -...

View Detail -

Super Purchasing for Pipe Turning Roller - 10T...

View Detail