OEM Supply Gate Welding Hinge - 5000kg Head & tail stock positioner – Wuxi Success Detail:

Head & Tail stock positioners generally handle the rotation of long work pieces around a horizontal centreline. This type is very special,it can lift by hydraulic,can rotate and tilt 360°,it make work convenient for welding.

Here Below is 5T Head & Tail Stock Welding Positioner Specification:

Welding Positioner Description:

1.Head and Tail stock welding positioners work through the two ends of the long work piece clamping,and can adjust the height via hydraulic system to achieve the ideal position.

2.The clamps can be designed according to your work piece.

3. Typically a Head & Tailstock Welding Positioner is used for long rectangular shapes that must be supported from both ends.

4. It can be adopted by electric welding Rotary achieve the desired location.

5. Head Stock welding positioner can overturn and tilt the work piece 360°.

6. Voltage is 220V,380V,415V,600V, 50 / 60Hz , 3Ph. Or as your required.

7.100% new from manufacture-Wuxi Success Machinery Equipment CO.,LTD.

Our Suggestions On Head & Tail Welding Positioner :

1. If your work piece is pipe, please advise us the pipe diameter for the welding chuck model.

2. If your work piece is too long or high , please advise us in advance,then we can adjust the positioner table center height .

3. If you want the clamps for your special work piece , then please advise us the details drawings,we also can produce for you.

Head & Tail Stock Welding Manipulator Feature:

1. We have 3 jaws or 4 jaws chucks for chosen.

2. Special clamps are available,but we have to design according to your work piece detail drawings.

3. Bolt fixed the work piece on the turning table then weld with the automatic welding guns.

4. It can joint welding column and boom manipulator working.

Hydraulic Head And Tail Stock Positioner Spare Parts Brand:

1. Rotary welding positioner Inverter is Danfoss / Yaskawa.

2. Head stock and Tail stock positioner Electric system is Schneider.

3. Welding rotary positioner Motor is Invertek.

4.CE certificates to European market and America market.

More Questions Customers May Concerned On Our Welding Machine:

Q : What about the transportion?

A : 1. Fully packaged in wooden case to anti damage during the transportational process .

2. Usually we take seaway ,cause its more convenient and cheaper for big machine.

3. Door to door delivery service is also available.

Q : What is your warranty and after sale service ?

A : 1. All our equipments with One Year Warranty time , fully test at our work shop before delivery.

2. If you have any questions on the installation , you will get our engineers respond within 24 hours.

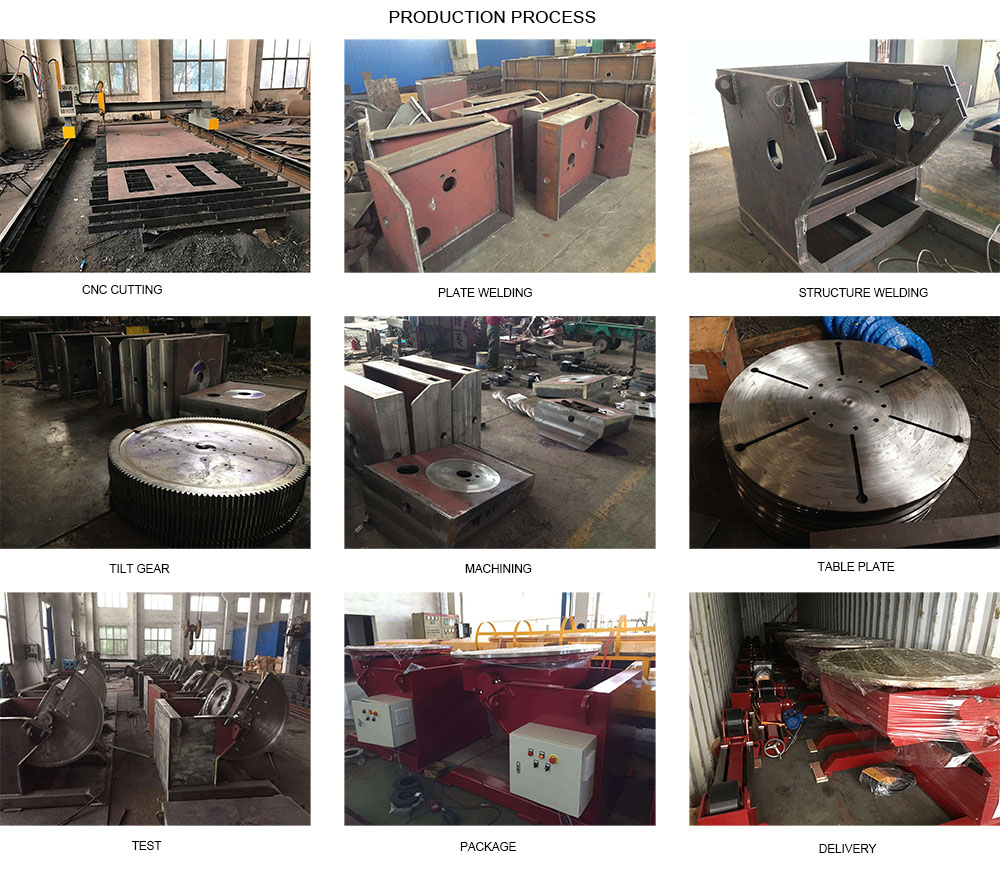

Product detail pictures:

Related Product Guide:

Pipe Welding: What If It Turned Out The U.S. Will Soon Be The Top Oil Producer In The World?

Turning Rolls Are the Best Welding Supplies

We purpose to understand high quality disfigurement with the output and supply the top service to domestic and overseas buyers wholeheartedly for OEM Supply Gate Welding Hinge - 5000kg Head & tail stock positioner – Wuxi Success, The product will supply to all over the world, such as: Denver, Detroit, Turkmenistan, Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it. Faster delivery time and the product you want is our Criterion .

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!