OEM/ODM China Welding Positioner With Chuck - 5T Conventional Welding Rotator – Wuxi Success Detail:

Wuxi Success designed and manufactured the welding rotator series product according to the operation requirements of several pressure vessel factories.The series conventional pipe welding rollers stand is able to adopt to various diameter of job, by adjust the center distance of rollers, via reserved screw holes or lead screw. It is produced according with mechanical standard JB/T 9187-1999.

Here Below is 5T Conventional Welding Rotator used for light pipe vessels Specification:

| Model | CR-5 |

| Load capacity – Drive | 2.5 tons maximum |

| Load capacity – Idler | 2.5 tons maximum |

| Load capacity – Set | 5 tons maximum |

| Rotation capacity | 5 tons maximum |

| Vessels diameter | Min. 250mm ~ Max.2800mm |

| Rotation speed | 100~1000 mm/min VFD |

| Rotation power | 2*0.37kw with fan cooling |

| Roller wheels | PU (Polyurethane wheels) |

| Control way | Remote hand control + Foot pedal |

| Input Voltage | 110V ~ 575V Single/3 Phase 50/60Hz |

| Certificate | CE approval |

Bolt Adjustment Small Type Pipe Turning Rolls Description:

1. This type welding rollers always packaged One drive & one idler together in one wooden case as one set selling.

2. The Remote hand control, Radio hand control & Foot pedal control are all avaialble.

3. The series conventional pipe tuning welding rotators stand is able to adopt to various diameter of job, by adjust the center distance of rollers, via reserved screw holes.

4. Power roller of the welding rotator is driven by double motor. Reducer adopts cycloidal planetary gear reducer or worm reduction gear mode.

5. This type conventional welding turning rolls can joint control with other equipments such as welding manipulator,welding machine, welding positioner and so on.

6. 100% new from original manufacturer – WUXI SUCCESS MACHINERY EQUIPMENT CO., LTD.

All Welding Rotator Turning Rolls, Small and Large Rotator spare parts brand:

1.Our welding roller Inverter is from Danfoss / Yaskawa

2.Our welding rotator Motor is from Invertek

3.Our Tank rolls Reducer is from China brand

4.Our welding Electric system is from Schneider

Tank Welding Rotator Pressure Vessels welding Rollers Oil Tank Turning Rolls Used For Seam Welding Paniting Feature:

The conventional welding rotator is mainly used for the welding,polishing,painting and assembly of cylindrical roller shell. It also can assembling or using together with other tooling for the cone inequality diameter rotary.The Rotator base fabrication, or chassis, is designed and fabricated to carry the weight of the vessel / Job and incorporates a contingency for shock loading. It is important that the design eliminates any distortion which can lead to misalignment of the rollers.

Our related welding machine product name used for pipe turning welding :

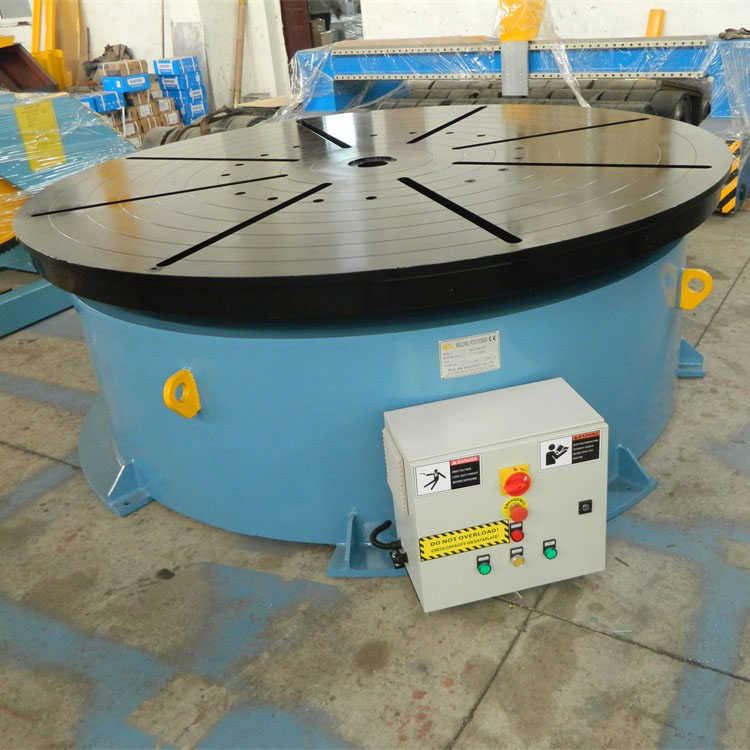

welding rotator ,weling positioner,welding manipulater,used pipe turning rolls,pressure vessels welding rotator,conventional welding rotator,pipe tank welding totator,rotation welding machine,Hydraulic Roator For Welding,Sand Blast Turning Roll,Automatic Welding Rollers,Tank Roller Welding Machine,Cylinder Pipe Welding Rotator,Conventional Tank Turning Rolls,head tail stock welding positioner,hydraulic welding positioner,lift welding positioer,horizontal welding positioner,Height Adjustment Welding Positioners,Turn Table Welding Positioner,Turn Table Welding Positioner,welding column boom,Auto Welding Boom,Tank Polishing Machine,column and boom,Column And Boom Manipulator,column boom welder

Product detail pictures:

Related Product Guide:

Turning Rolls Are the Best Welding Supplies

Pipe Welding: What If It Turned Out The U.S. Will Soon Be The Top Oil Producer In The World?

With advanced technologies and facilities, strict quality control, reasonable price, superior service and close co-operation with customers, we are devoted to providing the best value for our customers for OEM/ODM China Welding Positioner With Chuck - 5T Conventional Welding Rotator – Wuxi Success, The product will supply to all over the world, such as: United States, Indonesia, Turin, By integrating manufacturing with foreign trade sectors, we can provide total customer solutions by guaranteeing the delivery of right products to the right place at the right time, which is supported by our abundant experiences, powerful production capability, consistent quality, diversified products and the control of the industry trend as well as our maturity before and after sales services. We'd like to share our ideas with you and welcome your comments and questions.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!

-

Factory Price Jade Facial Roller - 80T Self Al...

View Detail -

Hot-selling Rubber Coated Conveyor Rollers - 5...

View Detail -

Cheap price Collecting Turning Table - 2000kg ...

View Detail -

Trending Products Miller Welding Machine - 300...

View Detail -

Big discounting pneumatic Positioner - 3000kg ...

View Detail -

Big Discount Cast Iron Surface Plate - 10×...

View Detail