Top Suppliers Machine For The Production - 80T Self Aligning Rotator – Wuxi Success Detail:

The self-aligning welding rotators are designed so that the rollers automatically align to accommodate different vessel diameters. All four axes of the drive unit are motorized to ensure smooth rotation and even weight distribution. This pressure distribution offers a special advantage when working with thin-walled workpieces because it reduces the chance of distortion of the workpiece.These welding rotators are used for the rotation and positioning of heavy, rotationally symmetrical workpieces like tanks, pipes or boilers for further machining or welding.

Here below is the 80T Pipelines Turning Roll specification:

Pipe Welding Turning Roller PRODUCTS FEATURES:

1. Our welding rollers pack One drive piece roller & one idler piece roller together as one set for sale.

2. Remote hand control, Radio hand control & Foot pedal control are all avaialble.

3. Top-class electronic components from Schneider to ensure long time using life.

4. Our tank tuning rolls’ drive rotation speed is in digital readout.

5. 100% new from original manufacturer – WUXI SUCCESS MACHINERY EQUIPMENT CO., LTD.

6. If your single pipe length more than 8 meter, we suggest you choose one drive roller and two idler rollers to support.

Competitive Advantage From Wuxi Success Pipe Welding Rollers:

1.Our welding roller Inverter is from Danfoss / Yaskawa

2.Our welding rotator Motor is from Invertek

3.Our Tank rolls Reducer is from China brand

4.Our welding Electric system is from Schneider

5.Frequency speed control is applied for the adjustment of roller speed.

6.Polyurethane(PU) rollers are more durable and wearable.

7.Double drive speed up rollers’ torque.

8.Rollers material could also be black rubber or Polyurathane rollers.

9.Could be designed as movable, lifting and anti-drift types.

More Questions Customers May Concerned On Our Welding rollers:

Q : What about the transportion?

A : 1. Fully packaged in wooden case to anti damage during the transportational process .

2. Usually we take seaway ,cause its more convenient and cheaper for big machine.

3. Door to door delivery service is also available.

Q : What is your warranty and after sale service ?

A : 1. All our equipments with One Year Warranty time , fully test at our work shop before delivery.

2. If you have any questions on the installation , you will get our engineers respond within 24 hours.

Q3: Can your machine or other products be customized?

A: yes, we are a professional manufacturer specializes in welding equipments about 15 years. We have a strong design team to meet requirements of customers.

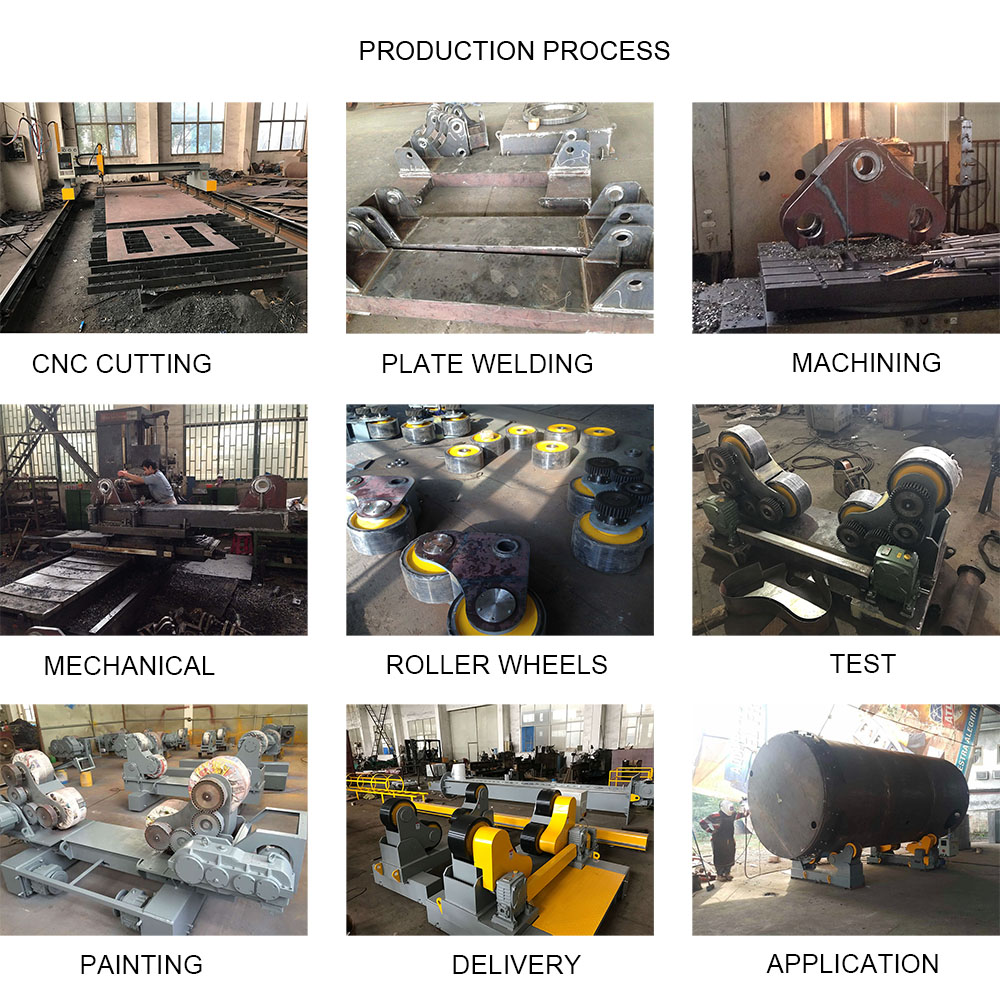

Product detail pictures:

Related Product Guide:

Turning Rolls Are the Best Welding Supplies

The Purpose of Welding Positioners in the Manufacturing Industry

We have been convinced that with joint attempts, the business enterprise between us will bring us mutual benefits. We could guarantee you product or service good quality and aggressive value for Top Suppliers Machine For The Production - 80T Self Aligning Rotator – Wuxi Success, The product will supply to all over the world, such as: Chile, Tanzania, Malaysia, Now, we professionally supplies customers with our main products And our business is not only the "buy" and "sell", but also focus on more. We target to be your loyal supplier and long-term cooperator in China. Now, We hope to be the friends with you.

Problems can be quickly and effectively resolved, it is worth to be trust and working together.