Wholesale Dealers of Automatic Tank Girth Welding Machine - 3000kg Gear tilt positioner – Wuxi Success Detail:

The welding positioner includes various types and it is usually combined with automatic welding system, such as manipulator and welding machine. With rotary and overturning of working table, the welding and fitting can be located at the right position. If connected with other welding devices, it can be turned into a half-automatic or full automatic welding machine. The gyration of working table can use electromagnetic speed variation or frequency control. And it mainly consists of a working table, turning device, overturning device, electricity-conducting device, stander and electric cabinet.

Here Below is 3000KG Gear Tilt Positioner Specification:

| Model | HBJ-30 |

| Load capacity | 3000kg maximum |

| Table diameter | 1400mm |

| Tilting angle | 0-90°/ 0-120° |

| Tilting speed | 0.23 rpm |

| Tilting power | 2.2 kw |

| Rotation speed | 0.05-0.5 rpm |

| Rotation power | 1.5 kw |

| Control way | Remote hand control + Foot pedal |

| Input Voltage | 110V ~ 575V Single/3 Phase 50/60Hz |

| Certificate | CE approval |

Automatic Welding Positioner Description:

1. Welding positioner is consisting of worktable revolving mechanism, overturning device and electric control system.

2.Remote hand control box with digital rotation speed readout & foot pedal control for tilting control..

3.Positioner can tilting from 0 to 120°, rotating 360° by VFD.

4. Stepless adjustable speed of the table rotation. Top-class electronic components from Schneider.

5.It’s Convenient for assembling intricate sub-assemblies,and ideal for in conjunction with Column & Boom.

6. 100% new pipe welding positioner from Wuxi Success Machinery Equipment CO.,LTD

Our Welding Positioner Machine Competitive Advantage:

1.Our welding rotary table Inverter is from Danfoss / Yaskawa.

2.Our automatic welding positioner Electric system is from Schneider.

3.Our gear tilt welder positioner turntable’ Motor is brand Invertek.

4.CE certificates to European market and America.

Welding Table With Positioner Application:

Welding positioners enable large, bulky or awkward workpieces to be accurately positioned to achieve the ‘down hand’ welding position without the need for overhead cranes or additional manpower or handling equipment.

1. Pressure vessels

2. Pipe manufacturing industries

3. Wind power fabrication

4. Chemical & fuel storage tank fabrication

5. Any heavy cylindrical job

Installation and after sale service:

1.The positioner will be fully installed and debugging before package for delivery .

2.We also supply the installation service at your work shop if needed.

3.One year warranty for welding positoner quality and free supported for spare parts.

4.Overseas agent is available in Italy and America market.

More Questions Customers May Concerned On Our Welding Positioner:

Q1 : What about the transportion?

A : 1. Fully packaged in wooden case to anti damage during the transportational process .

2. Usually we take seaway ,cause its more convenient and cheaper for big machine.

3. Door to door delivery service is also available.

Q2: Can your machine or other products be customized?

A : yes, we are a professional manufacturer specializes in welding Positioner about 15 years. We have a strong design team to meet requirements of customers.

Q3: Can your machine or other products be customized?

A : yes, we are a professional manufacturer specializes in welding equipments about 15 years. We have a strong design team to meet requirements of customers.

Q4: Quality Process Control:

A : All the machines are done testing before shipment. A 30min trial working is executed to guarantee the machine be faultless.

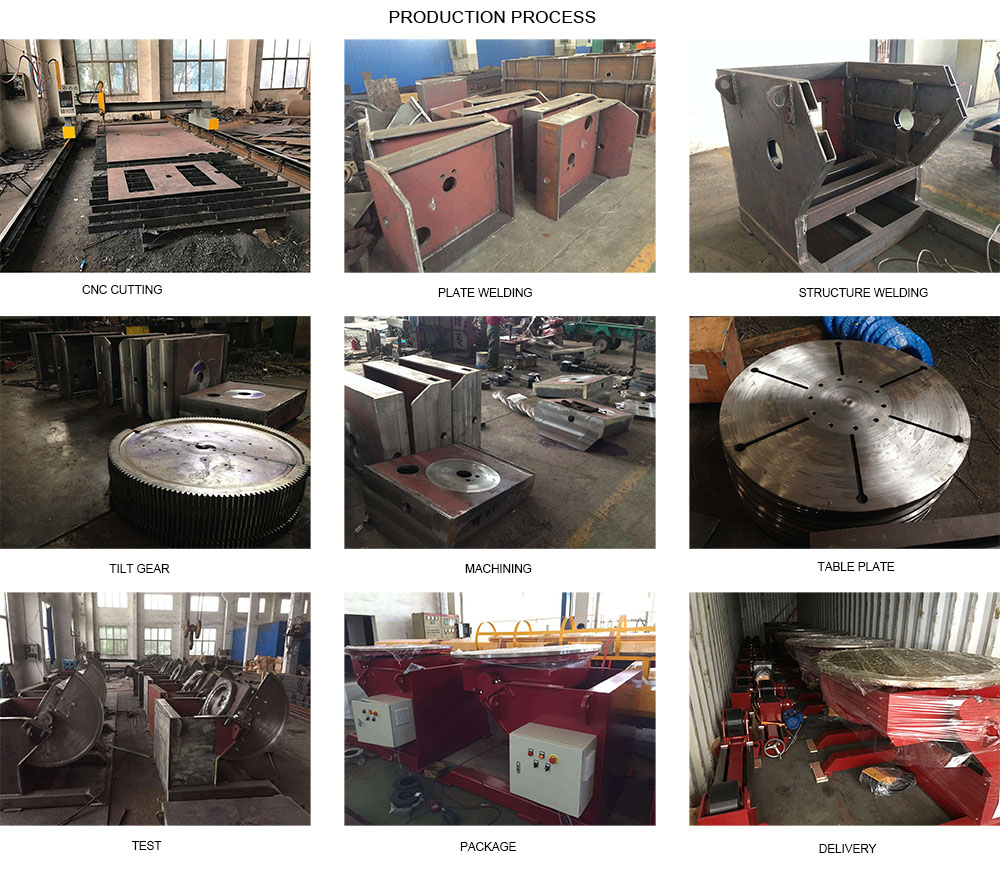

Product detail pictures:

Related Product Guide:

The Purpose of Welding Positioners in the Manufacturing Industry

Turning Rolls Are the Best Welding Supplies

Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs for Wholesale Dealers of Automatic Tank Girth Welding Machine - 3000kg Gear tilt positioner – Wuxi Success, The product will supply to all over the world, such as: Mumbai, Mexico, Norway, Since the establishment of our company, we've realized the importance of providing good quality goods and the best before-sales and after-sales services. Most problems between global suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question points they do not understand. We break down these barriers to ensure you get what you want to the level you expect, when you want it.

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.

-

Fast delivery Zorb Ball For Bowling - 100T Con...

View Detail -

China Cheap price 40t Pipe Welding Rollers - 6...

View Detail -

Factory source Tmt Bar Bending Machine - 1000k...

View Detail -

Super Purchasing for Single Base Frame Hydrauli...

View Detail -

Best quality Rotating Laser Levelling Equipment...

View Detail -

OEM China Rotating Welding Washing Nozzle - 50...

View Detail