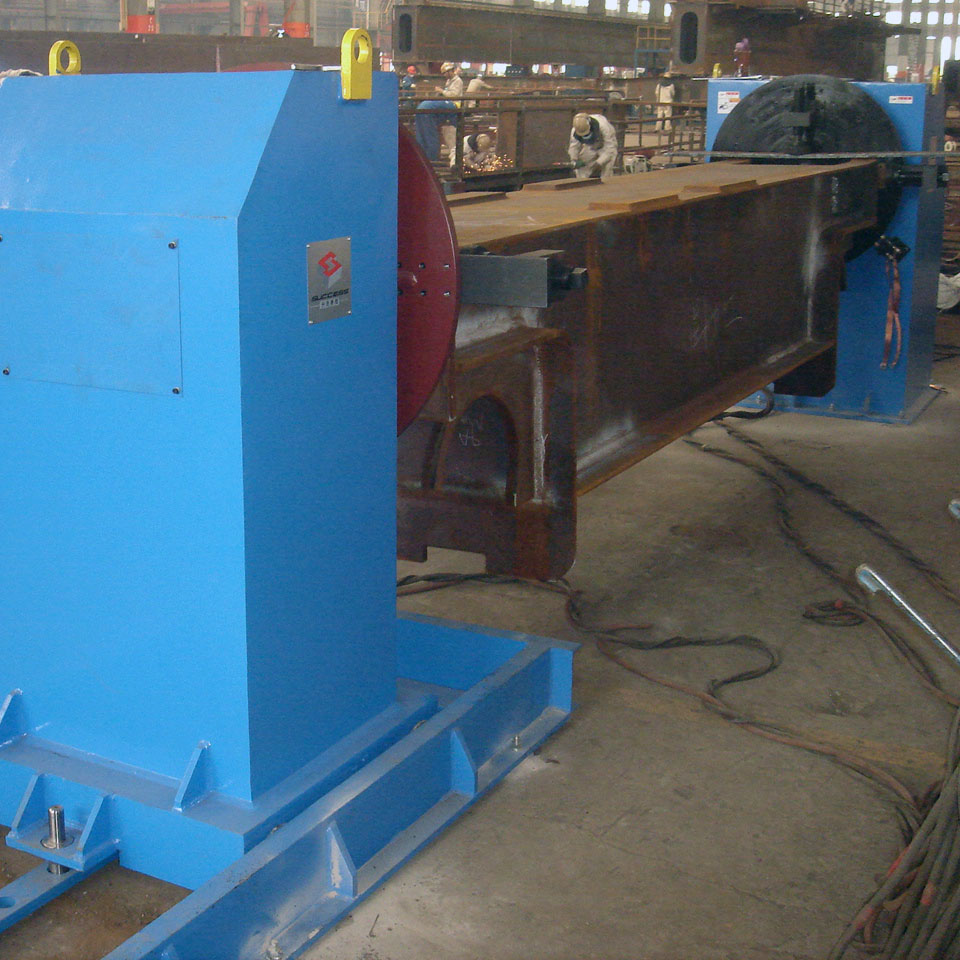

Wholesale Internal Welding Machine - 2000kg Head & tail stock positioner – Wuxi Success Detail:

Vertical rotary welding positioners of the Head & Tail stock positioner are used for Pipe to pipe ,Shaft, dish, cylinder, Framework of car, digger arm, loading machine, digger machine welding.

Here Below is 2T Head & Tail Stock Welding Positioner Specification:

| Model | HTWB-20 |

| Load capacity | 2000kg maximum |

| Table diameter | 1300mm |

| Rotation speed | 0.05-0.5 rpm |

| Rotation power | 1.1 kw |

| Control way | Remote hand control + Foot pedal |

| Input Voltage | 110V ~ 575V /3 Phase 50/60Hz |

Welding Turntable with positioner Positioner Description:

1. Export to USA market with 480V 60Hz 3P voltage.

2. Infinitly variable turning speed, achieved by an inverter controlled motor gearbox .

3. Rotation speed is digital readout on the electric box.

4. Welding Turn Table can rotate 360° by VFD control.

5. Controlled is remote-control box, optional foot switch or tilting angle if you wanted.

6. The clamps can be designed according to your work piece.

Head And Tail Stock Positioner Spare Parts Brand:

1. Rotary welding positioner Inverter is Danfoss / Yaskawa.

2. Head stock and Tail stock positioner Electric system is Schneider.

3. Welding rotary positioner Motor is Invertek.

4.CE certificates to European market and America market.

Workpiece welding way:

1. We have 3 jaws or 4 jaws chucks for chosen.

2. Special clamps are available,but we have to design according to your work piece detail drawings.

3. Bolt fixed the work piece on the turning table then weld with the automatic welding guns.

4. Using together with the auto welding robot.

5. Just advise me yours requestion for detail proposal.

After Sale Service From Wuxi Success Machinery Equipment CO.,LTD:

1. All our welding machine have passed CE test and get the CE certificates.

3. Fully installed and debugging before package and delivery, so its easy for your to installation at your work shop.

4. Door to door installation service is also available if customer needed.

5. We provide 12month guaranty period for the whole machine quality.

6. We have enough spare parts for after-selling.

Our Related Welding Machine Products Name:

welding positioner,pipe positioner,2 axis hydraulic welding positioner, L-Type Positioner,H-Type Positioner,Small Welding Positioner,Tank Welding Positioner,light duty welding positioner,rotary welding positioner,horizontal turntable,rotary turntable,head & tail stock positioner,Welding Column And Boom,Horizontal Pipe Rollers,column and boom,Column Boom Manipulator,Pipe Welding Manipulator,Cross Welding Manipulator,Cylinder Welding Manipulator,Automatic Feeding Manipulator,Wind Tower Manipulator Machine, pipe welding roller, pipe turning rolls, pipe welding roller, tube turning rolls, fit up rotator, self-aligned pipe welding roller stand, , self adjustable pipe welding roller stand, self aligned roller stand, wheel frame, automatic adjustable welding pipe rotator, conventional pipe welding roller stand, bolt adjustable pipe welding roller stand, sand blasting rotator, painting rotator, 1+1 hydraulic fit up rotator,welding positioner,welding column and boom,column boom manipulator,Automatic Feeding Manipulator,Heavy Duty Welding Manipulator,welding manipulator for pipe,Manipulator Welder.

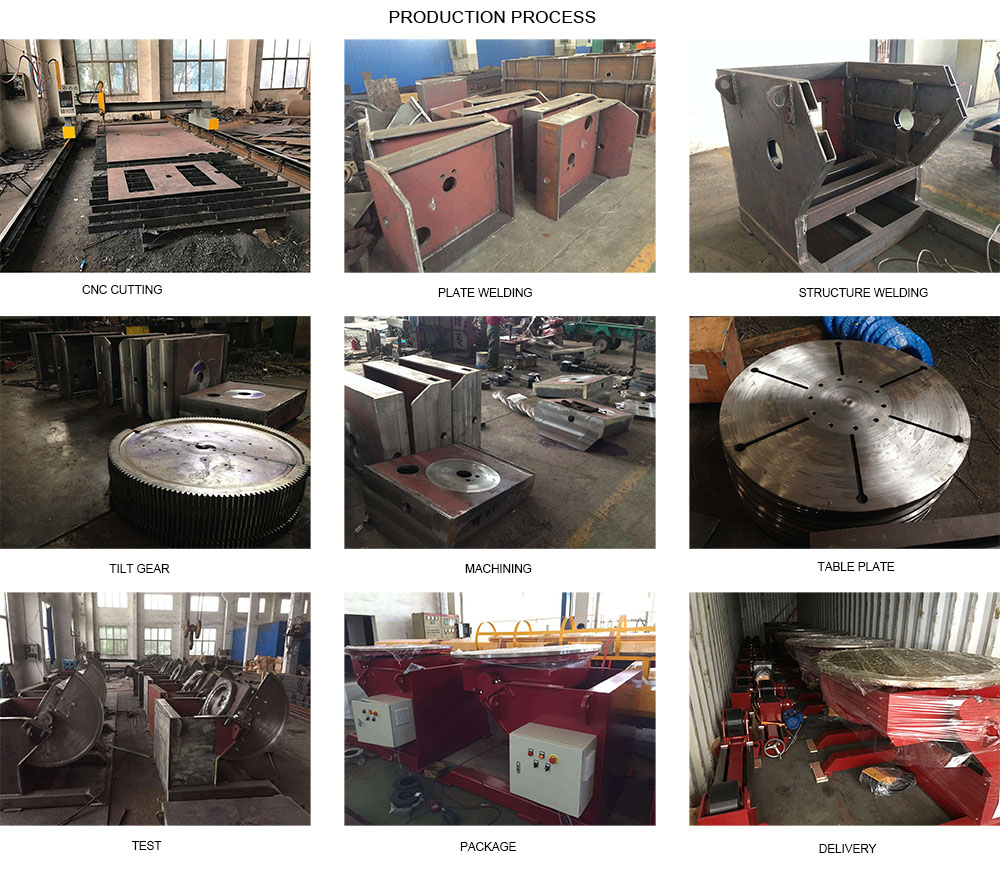

Product detail pictures:

Related Product Guide:

Pipe Welding: What If It Turned Out The U.S. Will Soon Be The Top Oil Producer In The World?

The Purpose of Welding Positioners in the Manufacturing Industry

We thinks what clients think, the urgency of urgency to act from the interests of a client position of theory, allowing for greater quality, lessen processing costs, price ranges are much more reasonable, won the new and outdated shoppers the support and affirmation for Wholesale Internal Welding Machine - 2000kg Head & tail stock positioner – Wuxi Success, The product will supply to all over the world, such as: Algeria, Denmark, Gambia, Our company warmly invites domestic and overseas customers to come and negotiate business with us. Allow us to join hands to create a brilliant tomorrow! We've been looking forward to cooperating with you sincerely to achieve a win-win situation. We promise to try our best to deliver you with high quality and efficient services.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.

-

OEM/ODM Factory Cnc Machine For Sale - 2000kg ...

View Detail -

Factory Price For 50t Pipe Turning Welding Roll...

View Detail -

Manufacturing Companies for Cnc Turning Roller ...

View Detail -

Factory wholesale L Type Positioner - 1000kg G...

View Detail -

China Gold Supplier for Hoist Swivel Ring - 40...

View Detail -

High Quality for Longitudinal Welding - 1000kg...

View Detail